With

Creo Elements/Pro Expert Moldbase Extension you can create mold base

designs in a process-driven, familiar 2D GUI and automatically generate a

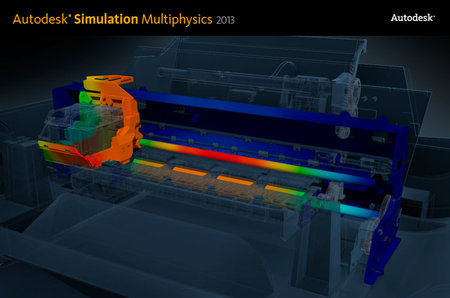

3D model to check for interference during mold opening. Automated

design steps as well as libraries with numerous standard parts and

components drastically speed up the entire development process.

Creo Elements/Pro Expert Moldbase Extension supports the efficient design of

injection mold

tools and as an ideal addition to Creo Elements/Pro Tool Design Option

(TDO). While TDO concentrates on the design of core and cavity EMX

allows extremely efficient design of the entire moldbase, including

typical functional units like ejector pins, screw connections, cooling

etc. Thus design time for mold tools can be reduced dramatically.

- Specialised 2D GUI for instant customisation of moldbases and components

- Automatic assembly of components – ‘pick & place’ ease

- All necessary clearance holes, threads, counterbores, etc. are automatically added to plates

- Part-level features already fully dimensioned

- Custom components can be created, saved and reused

- Automatic layers and simplified representations for easy viewing

- Standard and nonstandard mold components are marked

- Ability to take your customer parts through the complete process

-

Supplier catalogs include: DME, DMS, EOC, FUTABA (Misumi), HASCO, KLA,

MEUSBURGER, PEDROTTI, RABOURDIN, STRACK, PROGRESSIVE, NATIONAL, PCS and

others

- Automatic functions for: Complete Moldbase Assemblies;

Plates and Insulation; Guide, Leader and Return Pin Assemblies;

Multi-Cavity and Family Molds Supported; Support Pillar Assemblies;

Latch Lock Assemblies; Locating Rings and Sprue Bushing; Ejector Pins,

including Sleeve Ejection; Screws and

Washers; Dowel Pins; Cooling Circuit with Fittings, Plugs and O-Rings; Slider and Lifter Assemblies

- Automatic Drawing, Hole Chart and BOM Creation

- Mold Opening and Ejection Simulation

- Capturing Company Specific Best Practices and Standards in catalogues

با سلام به شما دوست عزیز

با سلام به شما دوست عزیز